Sapphire single crystals are typically grown using the Kyropoulos (KY), Czochralski (CZ), or Heat Exchange Method (HEM). These processes require extremely high temperatures between 1800–2100°C to melt high-purity alumina and allow it to crystallize slowly. Therefore, all high-temperature structural materials used in the furnace must exhibit excellent heat resistance, chemical stability, and thermal conductivity.

Contact Us

Sapphire single crystals are typically grown using the Kyropoulos (KY), Czochralski (CZ), or Heat Exchange Method (HEM). These processes require extremely high temperatures between 1800–2100°C to melt high-purity alumina and allow it to crystallize slowly. Therefore, all high-temperature structural materials used in the furnace must exhibit excellent heat resistance, chemical stability, and thermal conductivity.

Molybdenum wires, tungsten wires, molybdenum rods, and tungsten rods are commonly used as resistance heating elements. They provide excellent high-temperature electrical stability and can operate at 1800–2200°C without significant evaporation, suitable for long-term use in vacuum or inert atmospheres.

Typical materials: Molybdenum (99.95%), Tungsten (99.95%), and MoLa (molybdenum-lanthanum alloy).

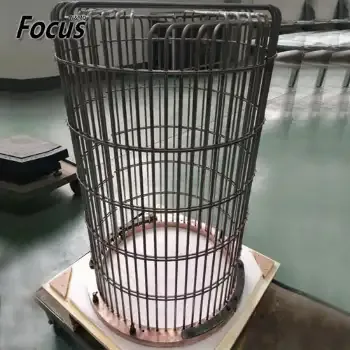

Made from molybdenum or tungsten sheets, these multilayer shields reduce heat radiation loss and improve temperature uniformity within the furnace. A 3–7 layer structure is typically used, with molybdenum as the inner layer and tungsten as the outer layer. Mo + MoLa combinations are often used to enhance mechanical strength.

Crucibles are used to hold molten alumina. Molybdenum crucibles are preferred due to their low reactivity with Al₂O₃ melts. For higher temperatures or more reducing atmospheres, tungsten crucibles can also be used. They must have smooth surfaces and high purity (>99.95%) to avoid contaminating the sapphire crystal.

Molybdenum rods, bolts, rings, and tungsten bases serve as structural supports under high temperatures. They have excellent thermal expansion compatibility, ensuring furnace stability. TZM (titanium-zirconium-carbon molybdenum alloy) is often used to enhance strength and creep resistance.

Made from molybdenum or tungsten alloys, these parts must maintain excellent mechanical stability at high temperatures and must not react with or contaminate the sapphire crystal.

Property

Molybdenum (Mo)

Tungsten (W)

Application Recommendation

Melting Point (°C)

2620

3410

Tungsten for ultra-high temperature zones

Density (g/cm³)

10.2

19.3

Tungsten is heavier and more stable

Thermal Conductivity

Excellent

Superior

Both suitable for shields and heaters

Machinability

Good

Poor

Molybdenum is easier to fabricate

Cost

Lower

Higher

Select based on budget and temperature range

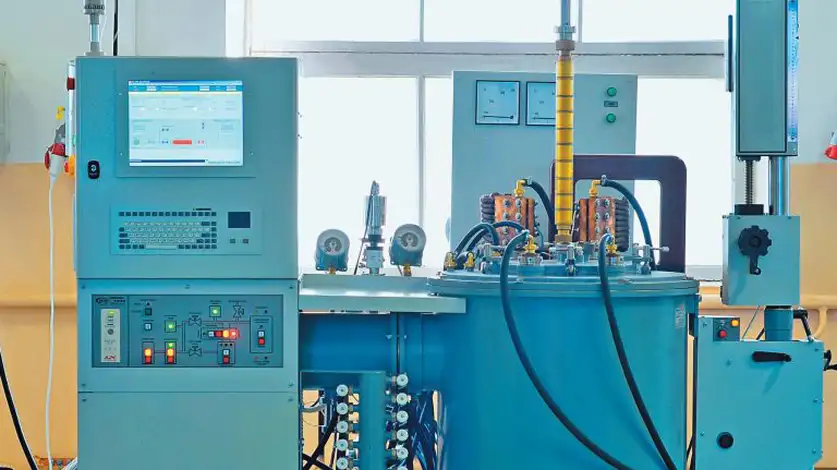

From the inside out, the typical sapphire growth furnace structure includes:

Sapphire crystal → Seed rod (Mo/W) → Crucible (Mo) → Heating element (Mo/W wire) → Heat shield (Mo/W sheet) → Support frame (Mo/TZM) → Outer shell (stainless steel).

Component

Main Material

Key Characteristics

Heating element

Mo wire, W wire

High-temperature stability, excellent conductivity

Crucible

Mo, W

High melting point, corrosion resistance

Heat shield

Mo sheet, W sheet

Insulation, temperature uniformity

Support frame

TZM, Mo

High strength, anti-creep performance

Seed holder

Mo, W

Stable, non-contaminating

+86 18625974739

focuswmo@outlook.com

High Tech Industrial Zone, Xiyuan International, Jianxi District, Luoyang City, Henan Province

WeChat

WeChat

Get a quote