Tungsten, molybdenum, and their alloys possess high melting points, excellent strength, good thermal stability, and outstanding creep resistance. These characteristics make them ideal structural and heating materials for use in vacuum, high-temperature, and inert gas environments. In the vacuum furnace industry, tungsten and molybdenum products are widely used in various types of vacuum heat treatment furnaces, vacuum brazing furnaces, and vacuum sintering furnaces due to their superior physical and chemical properties.

Contact Us

1. Heating Elements

Tungsten wire, molybdenum wire, tungsten strips, and molybdenum strips are commonly used as heating elements in vacuum furnaces. They feature excellent high-temperature stability, suitable resistivity, and long service life.

2. Reflective and Heat Shields

Reflective shields made of tungsten or molybdenum plates effectively reduce heat loss, ensure uniform furnace temperature, and improve energy efficiency.

3. Boats and Trays

Molybdenum boats, tungsten boats, and trays are used for holding and supporting work-pieces during sintering. They have high strength at elevated temperatures and do not react with the materials being processed, making them suitable for sintering metals, ceramics, and hard alloys.

4. Support and Fastening Components

Tungsten and molybdenum rods, screws, and nuts are used as structural supports inside the furnace, maintaining excellent mechanical strength and dimensional stability under high-temperature vacuum conditions.

5. Thermal Field Components

These include molybdenum frames and hybrid tungsten-molybdenum assemblies, which help ensure uniform temperature distribution, improve thermal efficiency, and enhance product quality.

Excellent High-Temperature Resistance:

Tungsten has a melting point of 3410°C and molybdenum 2620°C, suitable for ultra-high-temperature vacuum environments.

High Creep and Deformation Resistance:

Maintains stable shape during long-term high-temperature operation.

Low Vapor Pressure and Good Vacuum Compatibility:

Minimal evaporation loss under high vacuum, preventing contamination of the furnace atmosphere.

Good Thermal and Electrical Conductivity:

Enhances heating efficiency and temperature uniformity.

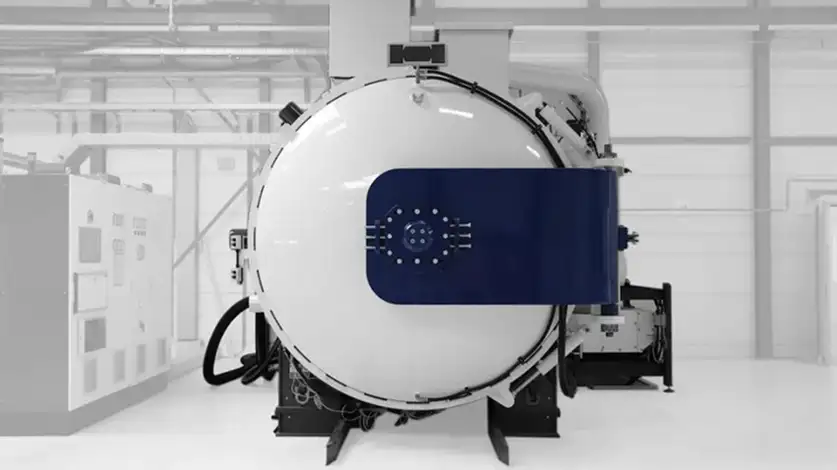

Vacuum heat treatment furnaces

Vacuum brazing furnaces

Vacuum sintering furnaces

Vacuum annealing furnaces

Single crystal growth furnaces

+86 18625974739

focuswmo@outlook.com

High Tech Industrial Zone, Xiyuan International, Jianxi District, Luoyang City, Henan Province

WeChat

WeChat

Get a quote